Baseline Model Updating using Truck Load Data and Strain Measurements

The Vernon Avenue Bridge over the Ware River in Barre, Massachusetts (Figures 1 and 2) is used for bridge Structural Health Monitoring (SHM). It is a continuous three span steel stringer bridge with composite reinforced concrete deck. The NSF Partnerships for Innovations (PFI) program has funded this project for three years. Dr. Sarah Nerlove is the program director for this project at NSF.

Instrumentation began in June 2009 by our students and was completed in October of 2009. Many different types of sensors were installed, including 100 strain gauges, 16 tiltmeters, 16 accelerometers, 30 concrete deck temperature sensors, 36 girder temperature sensors, 3 ambient temperature sensors and 2 pressure plates. A monitoring system was installed by Geocomp Corporation in order to capture structural behavior during construction and into the service life of the bridge (Figures 3 & 4). Strain data from the steel girders was collected during the concrete deck pour.

We have performed two rounds of bridge load tests on 9/3/2009 and 7/30/2010. The first test included both stop location and crawl speed load tests. The second test included both truck crawl-speed load testing and dynamic vibration excitation and acceleration measurements. We are also continuously monitoring the bridge for temperature effects and its impact on load rating and long term performance.

Figure 1. Completed Vernon Ave.

Figure 2. On-Site Data Acquisition System

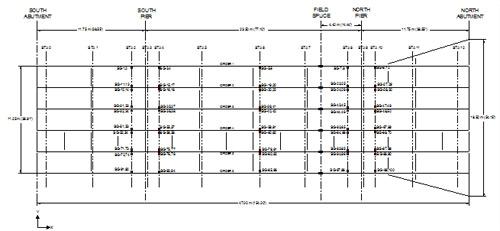

Figure 3. Vernon Avenue Instrumentation Plan

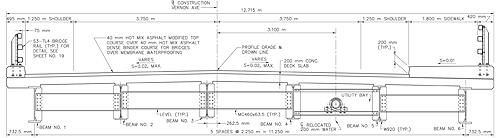

Figure 4. Vernon Avenue Section View (Courtesy of FST Inc.)

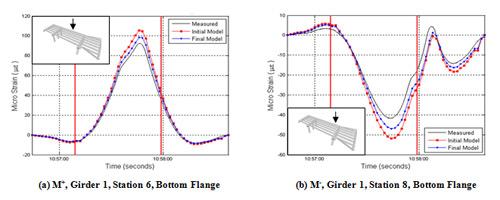

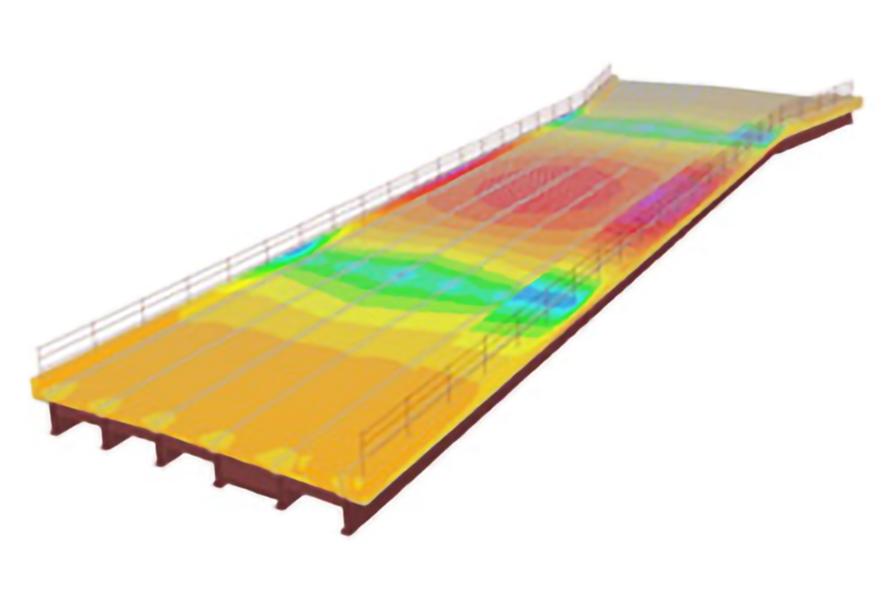

Two finite element models were created using shell/solid elements and frame/shell elements. Both computer model responses were compared with field strain measurements of the full scale bridge. Both the shell/solid and frame/shell FEMs produced close estimates of the measured strain data. The shell/solid model is shown in Figure 5 and a comparison of predicted and measured strains is shown in Figure 6. The predicted strains closely matched with the measured strains. The structural model that reflects the actual bridge 3D system behavior can be used for load rating and overload permitting.

Figure 5. FEM of the Vernon Ave. Bridge

Figure 6. Modeled and Measured Strains - Crawl Speed Load Test

The Research Team

Professor Masoud Sanayei of Tufts University served as Principal Investigator (PI), Associate Professor Erin Santini Bell of the University of New Hampshire served as the Co-PI, Professor of the Practice Brian Brenner as the Tufts University Co-PI and representative of FST as the main industrial partner, Dr. Allen Marr of Geocomp Corporation as the main partner for instrumentation and data acquisition.

Graduate Students

Students at Tufts University and the University of New Hampshire played a major role in instrumentation, data acquisition, and load rating of the Powder Mill Bridge over Vernon Avenue using the measured nondestructive test data. Several graduate students contributed to the success of this project including Jesse Sipple, John Phelps, Merve Iplikcioglu, Paul Rosenstrauch, and Peeyush Rohela of Tufts University and Paul Lefebvre, John Welch, Eric Picard and Jason Peddle of the University of New Hampshire.

Acknowledgements

The project was supported by a grant from the National Science Foundation, Partnership for Innovations Program. The Town of Barre, Owner of the bridge, provided access and ongoing help with coordination for all phases of the project. The Massachusetts Department of Transportation likewise provided coordination and assistance. Bridge constructor E.T.&L. Corporation, and the steel fabricator, High Steel, Inc, provided access, assistance and coordination during bridge construction.