Semiconductor Process Training Modules

The following equipment and capabilities are available. Please contact the TEC Facility staff for more information about specific equipment.

The Materials Characterization Laboratory service center within the TEC Facility suite houses a group of semiconductor fabrication modules designed for use by students as part of training in the basic processes of semiconductor and CMOS device fabrication. These modules are available for educational and limited general use.

Select modules are functional now, while the remainder will be available late 2019.

- EMS Modulab PVD system – single source thermal evaporator, available now, allowed materials are Al, In, and Au. Al is provided by the laboratory, please provide your own Au and In.

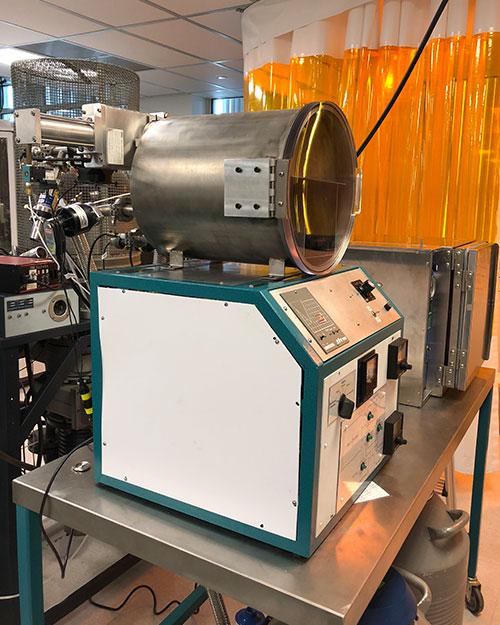

- 300C Vacuum Furnace – intended for low temperature dehydration bake of Si wafers and resist hard bakes, available for use now with limited sample types.

- EMS Modulab Photolithography and Spinner station – self-contained system for resist spin on, resist low temperature bake, low-resolution mask alignment, and low resolution UV exposure. Expected to be available late 2019.

- EMS Modulab Wet Process Bench – bench for resist development, resist strip, and rinse. Limited resist and developer options, contact staff for specifics. Expected to be available late 2019.

- EMS Modulab Wet Etch Bench – bench for Si wafer cleaning and oxide etch. Limited to select chemistries only, contact staff for specifics. Expected to be available late 2019.

- EMS Modulab Oxidation Furnace – 1300 °C capable oxide furnace for wet or dry thermal oxidation of Si wafers. Available now.

- EMS Modulab Diffusion Furnace – 1000 °C capable diffusion furnace for p-type doping of Si with Boron only. Expected to be available late 2019.

Wet Process and Wet Etch Benches

Thermal Evaporator