Capabilities

The following tools are available. Standard Operating Procedures are also available. Click on the title of each tool for more information.

- Ocean Optics Nanocalc UV-VIS Reflectometer

- Probestation

- Tegal Plasmod Oxygen Plasma Cleaner

- Thermolyne Muffle Furnace

- Zygo NewView 600S

Karl Suss MA6 Mask Aligner

The Suss MA6 contact aligner is a 350 W mercury lamp UV source contact aligner for performing photolithography. This MA6 is top side alignment only. The exposure source is controlled in constant intensity mode to 15 mW/cm2 at I-line (365 nm). Additional energy will be present at h-line and g-line bringing the total NUV exposure intensity to approximately 45 mW/cm2 (uncalibrated). The aligner can be operated in proximity, soft contact, hard contact, or vacuum contact modes. It accepts 4" (100 mm) wafers and 5" (125 mm) x 5" (125 mm) x 0.09" glass masks.

The tool requires training with an experienced user and formal checkout by laboratory staff.

Contacts: Robert White, James Vlahakis, Daniella Torres

Related Standard Operating Procedures:

OAI Model 204IR Mask Aligner

This manual mask aligner is capable of frontside alignment and backside alignment (using transmitted IR light). The aligner has soft contact, hard contact, and vacuum contact modes. The tool has a 350 Watt I-line Near UV lamp calibrated to 20 mW/cm^2 intensity at I-line (365 nm). Additional energy will be present at h-line and g-line bringing the total NUV exposure intensity to approximately 45 mW/cm2 (uncalibrated). It accepts 4" (100 mm) wafers and 5" (125 mm) x 5" (125 mm) x 0.09" glass masks.

This tool requires training and formal checkout with the faculty supervisor before you may operate it unsupervised. Read the SOP (see below). Then contact a qualified user and ask to observe tool operation. When you are comfortable with tool operation, contact Prof. White and arrange a formal checkout procedure. Once checked out, you are welcome to use the tool unsupervised.

Contacts: Robert White, Jim Vlahakis

Related Standard Operating Procedures:

- OAI Aligner

- Standard Photolithography (1800 series, SPR220 series)

- SU-8 Processing

- Photodefineable Polyimide Processing

- Polyimide Thinning Process

- AZ Series Photoresist Processing (AZ9245, AZ9260)

Laurell WS-400B-6NPP-Lite Manual Spinners

The manual spinners are used for spin coating photoresist onto wafers. Chucks are available for 2", 4", and 6" wafers and small wafer fragments. Maximum speed is 8000 rpm.

You may operate the spinner without going through a formal checkout procedure. However, you are required to read the SOP carefully, and arrange with a qualified lab user to demonstrate tool use to you before using it by yourself.

There is one "clean" spinner which may be used only with SPR series resists. The "dirty" spinner may be used with other materials such as SU-8, polyimide, and biopolymers.

Contacts: Robert White, Jim Vlahakis

Related Standard Operating Procedures:

Fume Hoods

The two fume hoods are used for all chemical processing. A compressed dry air gun is available, as well as house vacuum. Personal protective equipment, including eye protection, nitrile and Trionic gloves, and apron must be worn when working in the hood. For processing with strong acids a face shield must also be worn. Do not work with chemicals you are not familiar with. Read Material Safety Data Sheets, Standard Operating Procedures, and ask for help if you are not comfortable.

Contacts: Robert White, Jim Vlahakis

Related Standard Operating Procedures:

- HF Device Release

- Piranha Clean

- Organic Clean—RCA SC1

- GaAs Wafer Prep

- GaSb Wafer Prep

- SU-8 Processing

- PDMS Molding

- Standard Photolithography

- AZ Series Photoresist Processing (AZ9245, AZ9260)

- Silicon Dioxide Etching with Buffered Hydrofluoric Acid

- Wet Photoresist Strip with Remover 1165

- Anisotropic Wet Etching of Silicon using Potassium Hydroxide (KOH)

- Isotropic Wet Etching of Silicon using HF/Nitric/Acetic (HNA)

- Wet Etching of Chromium: Transene Type 1020 (nitric:ceric ammonium nitrate)

- Wet Etching of Gold: Gold Etch TFA (Potassium Iodide, Iodine)

- Wet Etching of Aluminum: Transene Aluminum Etch A (phosphoric:nitric:acetic)

- Wet Etching of Copper: Transene APS100 (ammonium persulfate)

- Wet Etching of Copper #2: 1:1:18 Acetic:Peroxide:Water

- Wet Etching of Silver: Nitric Acid

- Wet Etching of Titanium: 1:1:20 HF:Peroxide:Water

- Making a Glass Mask from a Transparency Mask

- Photodefineable Polyimide Processing (HD-4100 series)

- Non-Photodefineable Polyimide Processing (PI-2600 series)

- Polyimide Thinning Process

- Silk Fibroin Thin Film Processing

- Silk Processing with Bacteriorhodopsin (BR) and 3-(1-pyridinio) propane sulfonate (PPS)

- PolyVinylAlcohol Processing with Bacteriorhodopsin (BR) and 3-(1-pyridinio) propane sulfonate (PPS)

- PMMA E-beam Resist Processing

- Liftoff Processing for Metal Patterning

- Copper Electroplating

- Nickel Electroplating (Nickel Sulfamate)

Tescan VEGA3 Scanning Electron Microscope

The VEGA3 is a PC controlled SEM with electrostatic beam blanker and DrawBeam software, allowing it to be used for electron beam lithography applications. Direct write e-beam resolution in ebeam resists down to below 100 nm should be possible under good conditions.

Related Standard Operating Procedures:

NSC 3000 DC Magnetron Sputter Tool

The Nanomaster NSC-3000 DC magnetron sputter tool allows sputter deposition of metallic thin films. Cosputtering is available. Current target materials are Ti, Cr, Ni, Al, Ag, Cu, and Au.

This tool requires training with the tool contact and formal checkout by the faculty supervisor.

Contacts: Robert White, Jim Vlahakis

Related Standard Operating Procedures:

PDS 2010 Parylene Coater

The Specialty Coating Systems PDS2010 Labcoter 2 allows vapor phase deposition of the polymer Parylene (Poly-para-xylylene) type N, C, and D.

This tool requires training with the tool contact and formal checkout by the faculty supervisor.

Contacts: Robert White, Cinzia Metallo, Jim Vlahakis

Related Standard Operating Procedures:

Related Documents:

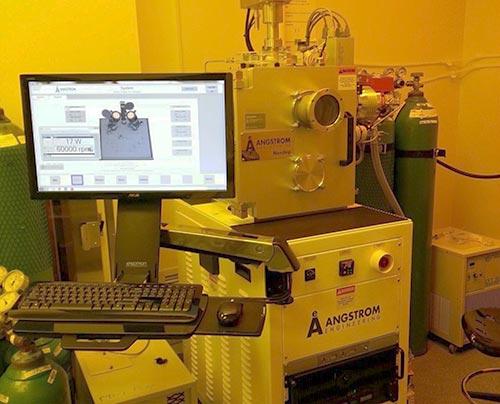

Angstrom NexDep DC/RF Sputter System

The NexDep sputter system is a dual gun sputter-up system with both DC and RF power supplies. Either gun can be run in DC mode sequentially (not at the same time). One gun can be run in RF mode. It is possible to co-sputter with one gun in DC mode and one gun in RF mode. The platen is heated. The standard sputtering gas in Argon. Reactive sputtering is also available with nitrogen delivered via a gas ring near the platen, and oxygen delivered via a wall port. Closed loop pressure control is maintained.

Currently the tool has recipes for DC sputtered Aluminum, DC sputtered Molybdenum, and RF sputtered SiO2. Development of an RF sputtered aluminum nitride process is ongoing. Additional material systems will be added as time progresses.

The tool requires training with an experienced user and formal checkout by laboratory staff.

Contacts: Robert White, James Vlahakis, Daniella Torres

Related Standard Operating Procedures:

Cambridge Nanotech Savannah Atomic Layer Deposition (ALD) System

The Savannah system is a very popular atomic layer deposition (ALD) platform. The substrate is heated in the vacuum chamber with a constant flow of carrier nitrogen. Reactive precursors are sequentially pulsed into the chamber for short periods of time (< 1 second) followed by a longer nitrogen purge (>5 seconds) which removes unreacted precursor from the chamber before the next precursor is pulsed in. This allows a single layer of material to be deposited per cycle, resulting in very fine thickness control, high uniformity across the substrate, and conformal depositions. Depositions are slow (on the order of 1 angstrom per cycle), so only thin films can be deposited.

A variety of chemistries are available for different materials. Currently, our ALD system has H2O, TMA (tetramethyl aluminum) and DEZ( diethyl zinc) precursors, allowing deposition of Al2O3 and ZnO thin films. At user request we will be happy to consider adding additional precursors to the system to support your processing needs.

The tool requires training with an experienced user and formal checkout by laboratory staff.

Contacts: Robert White, James Vlahakis, Pooria Mustafulu, Kevin Ligonde

Related Standard Operating Procedures:

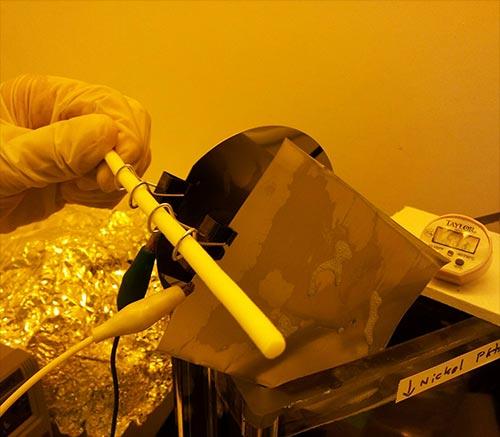

Copper, Nickel, and Gold Electroplating

Electroplating of thick films of copper, nickel, and gold using copper sulfate, nickel sulfamate, and gold sulfite plating chemistries. Films 10 or more microns in thickness can be deposited with deposition rates on the order of 100-200 nm per minute. The plating system can handle small pieces or wafers up to 100 mm in diameter. A conducting seed layer is required. Copper plating using a copper sulfate plating solution is conducted at room temperature. Nickel plating using a nickel sulfamate plating solution is conducted at 50 C. Gold plating using a gold sulfite plating solution is conducted at 58 C. See the procedures below for more details.

Related Standard Operating Procedures:

LC Tech Thermal Evaporator

Thermal evaporation is a common PVD process. Under vacuum, material is heated, driving increased vapor pressure and thus depositing onto the substrate (in fact, on all surfaces in the chamber). Substrates may vary from small pieces to entire 4" (possibly larger) wafers. Deposition rates are typically 1-3Å/s. The instrument has four sources so up to 4 materials may be deposited without breaking vacuum. The microfab supplies material and boats for Al, Ti and Cu. Other materials/boats (Au, Cr for example) must be supplied by the user. Allowed materials are Si, glass, Al, Au, Cu, Cr, Ti, and fully cured photoresists. Other materials will be considered on a case by case basis. Storage for user supplied materials and boats is available.

The tool requires training with an experienced user and formal checkout with laboratory staff.

Contacts: Robert White, James Vlahakis, Brian Timko

Related Standard Operating Procedures:

Fume Hoods

The two fume hoods are used for all chemical processing. A compressed dry air gun is available, as well as house vacuum. Personal protective equipment, including eye protection, nitrile and Trionic gloves, and apron must be worn when working in the hood. For processing with strong acids a face shield must also be worn. Do not work with chemicals you are not familiar with. Read Material Safety Data Sheets, Standard Operating Procedures, and ask for help if you are not comfortable.

Contacts: Robert White, Jim Vlahakis

Related Standard Operating Procedures:

- HF Device Release

- Piranha Clean

- Organic Clean—RCA SC1

- GaAs Wafer Prep

- GaSb Wafer Prep

- SU-8 Processing

- PDMS Molding

- Standard Photolithography

- AZ Series Photoresist Processing (AZ9245, AZ9260)

- Silicon Dioxide Etching with Buffered Hydrofluoric Acid

- Wet Photoresist Strip with Remover 1165

- Anisotropic Wet Etching of Silicon using Potassium Hydroxide (KOH)

- Isotropic Wet Etching of Silicon using HF/Nitric/Acetic (HNA)

- Wet Etching of Chromium: Transene Type 1020 (nitric:ceric ammonium nitrate)

- Wet Etching of Gold: Gold Etch TFA (Potassium Iodide, Iodine)

- Wet Etching of Aluminum: Transene Aluminum Etch A (phosphoric:nitric:acetic)

- Wet Etching of Copper: Transene APS100 (ammonium persulfate)

- Wet Etching of Copper #2: 1:1:18 Acetic:Peroxide:Water

- Wet Etching of Silver: Nitric Acid

- Wet Etching of Titanium: 1:1:20 HF:Peroxide:Water

- Making a Glass Mask from a Transparency Mask

- Photodefineable Polyimide Processing (HD-4100 series)

- Non-Photodefineable Polyimide Processing (PI-2600 series)

- Polyimide Thinning Process

- Silk Fibroin Thin Film Processing

- Silk Processing with Bacteriorhodopsin (BR) and 3-(1-pyridinio) propane sulfonate (PPS)

- PolyVinylAlcohol Processing with Bacteriorhodopsin (BR) and 3-(1-pyridinio) propane sulfonate (PPS)

- PMMA E-beam Resist Processing

- Liftoff Processing for Metal Patterning

- Copper Electroplating

- Nickel Electroplating (Nickel Sulfamate)

March CS1701F Reactive Ion Etcher

A March Plasma systems parallel plate RF plasma etcher. The tool has SF6, CF4, O2, and Ar gases available for etch. Materials that can be etched in this tool include silicon, silicon dioxide, silicon nitride, and organic polymers.

This tool requires formal checkout with the faculty supervisor prior to solo use. To learn , first use the tool with another qualified user to become familiar with operation before you request checkout.

Contacts: Robert White, Jim Vlahakis

Related Standard Operating Procedures:

ETP Corona Discharge Wand

The Corona discharge wand utilizes a high frequency generator to produce a plasma at the electrode tip. Useful in the temporary (on the order of several minutes) modification of certain surfaces - polymers can be modified for better adhesion to glass substrates, hydrophobic glass slides can become hydrophilic, etc.

Contacts: Robert White, Jim Vlahakis

Related Standard Operating Procedures:

SSI Rapid Thermal Processor

Through the use of high power heating lamps, the SSI RTP can heat samples (wafers, slides) up 1200°C on a time scale of several seconds. This can be useful for activating or driving dopants, growing oxide films, annealing interlayer contacts, etc. Great care must be exercised to prevent damage to the substrate or process chamber as a result of overheating.

This tool requires a formal checkout.

Related Standard Operating Procedures:

MicroAutomation MA1006 Dicing Saw

The MA1006 die saw is used for dicing silicon and glass wafers into smaller pieces. The tool is water cooled and located in the packaging area of the cleanroom.

This tool requires training with the tool contact and formal checkout by the faculty supervisor.

Contacts: Robert White, Jim Vlahakis

Related Standard Operating Procedures:

Marpet Enterprises MEI1204B Manual Ball Bonder

The manual ball bonder can be used for wirebonding chips to a package. The bonder is capable of handling gold and aluminum wire.

You must be checked out before using this tool by yourself.

Contacts: Zhengxin Zhao, Robert White

Related Standard Operating Procedures:

PDS 2010 Parylene Coater

The Specialty Coating Systems PDS2010 Labcoter 2 allows vapor phase deposition of the polymer Parylene (Poly-para-xylylene) type N, C, and D.

This tool requires training with the tool contact and formal checkout by the faculty supervisor.

Contacts: Robert White, Cinzia Metallo, Jim Vlahakis

Related Standard Operating Procedures:

Related Documents:

Tousimis Model 810 AutoSamdri Critical Point Dryer (CPD)

Critical point drying is used to reduce adhesion failure and collapse of compliant structures with small gaps during the drying process. This particular unit is intended for drying MEMS devices after the release step where capillary forces in small gaps can cause irreversible "stiction" failure of the device during drying. The process works by replacing the alcohol in which the device is bathed with liquid CO2 (at appropriately high pressures and temperatures somewhat below ambient), and then heating up and pressurizing the CO2 to pass into the supercritical phase, before returning to ambient conditions on the other side of the Liquid-Gas phase boundary, never having crossed the phase boundary and therefore never evolving a liquid-gas interface that would create high surface tension forces.

The Tousimis system is an automatic critical point dryer with a small (1.25" diameter) chamber. A chip holder that holds 5 10 mm dies is available.

The tool requires training with an experienced user and formal checkout by laboratory staff.

Contacts: Robert White, James Vlahakis, Kevin Ligonde

Related Standard Operating Procedures:

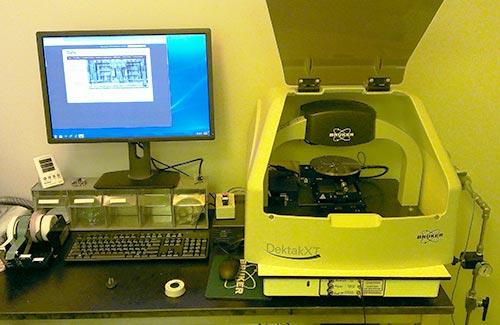

Stylus Profilometer – Dektak XT

The Dektak XT stylus profilometer employs a stylus scanned across a surface to characterize various features – step height, roughness, stress, etc. The instrument max step height is 1mm, max scan length is 55mm, resolution approximately 1nm, accuracy approximately 10nm.

No formal training or checkout is required. Please refer to the SOP and work with a more experienced user to become familiar with the tool.

Contacts: Robert White, Jim Vlahakis

Related Standard Operating Procedures:

Miller FPP-5000 4-Point Probe

The FPP-5000 4-Point Probe simplifies the measurement of resistive properties of semiconductor wafers and resistive films. The microprocessor based electronics permits direct computation of V/I, sheet or slice resistivity, metallization thickness and P-N type testing.

No checkout is required. Check with other lab users to make sure you are using the tool correctly.

Contacts: Robert White, Sam MacNaughton

Related Standard Operating Procedures:

Inspection Microscope

A reflectance-type inspection microscope is available. It has 10X eyepieces and planachromatic 4X, 10X, 25X, 40X objectives. It is set up with a 3 MPixel "QColor" firewire camera and image capture software.

No training or checkout is required.

Contacts: Everyone in the lab.

Related Standard Operating Procedures:

Tescan VEGA3 Scanning Electron Microscope

The VEGA3 is a PC controlled SEM with electrostatic beam blanker and DrawBeam software, allowing it to be used for electron beam lithography applications. Direct write e-beam resolution in ebeam resists down to below 100 nm should be possible under good conditions.

Related Standard Operating Procedures:

Denton Desk V Sputter Coater

Automated desktop sputter coater suitable for depositing thin metal films (typically Au) on specimens being prepared as SEM samples. Specimens should be mounted on 12.5mm stubs, several can be coated at one time. Process will deposit ~15-20nm film.

Related Standard Operating Procedures:

-

*This instrument has been decommissioned.

A UV-VIS reflectance-type spectrometer (Ocean Optics Nanocalc) is available. This tool is capable of measuring film thickness of semi-transparent thin films (oxide, nitride, polymer, polysilicon) using a UV-VIS spectrometer and model fitting.

This tool does not require a formal checkout. Use the tool with another user to become familiar with operation before you use it yourself.

Contacts: Robert White

Related Standard Operating Procedures:

-

*This instrument has been decommissioned.

A manual probestation is available for simple electrical continuity testing, resistance measurements, and capacitance measurements.

No checkout is required. Check with other lab users to make sure you are using the tool correctly.

Contacts: Robert White, Jim Vlahakis

-

*This instrument has been decommissioned.

This Oxygen plasma cleaner has a 4" diameter chamber (it can fit a single 4" diameter substrate). Generally, oxygen plasmas are used for removing organic residues and oxidizing surfaces. It is a RF Oxygen plasma cleaner with a 100 W power supply. Processing generally occurs between 100 mTorr and 300 mTorr. Manual control of pumps, gas flow, power, and RF tuning. There are no restrictions on the materials that can go into this tool.

Contacts: Robert White

Related Standard Operating Procedures:

-

*This instrument has been decommissioned.

The thermolyne benchtop muffle furnace is set up to flow nitrogen for annealing in a nitrogen environment. Maximum temperature is 1000oC. Ramp time is slow (10 mins. up, 1 hour down). Maximum sample size is a 4" wafer.

This tool does not require a formal checkout. Use the tool with another user to become familiar with operation before you use it yourself.

Contacts: Robert White

Related Standard Operating Procedures:

-

*This instrument has been decommissioned.

The Zygo NewView 600s is a non-contact surface profilometer that uses white light interferometry to measure surface profiles and surface roughness with sub-nanometer precision.

No formal training or checkout is required. Please refer to the training documents and work with another user to become familiar with the tool.

Contacts: Robert White, Jim Vlahakis

Related Standard Operating Procedures: