Unexpected mentorship provides rewarding experience

Last summer, Professor Eric Miller of Tufts University’s Department of Electrical and Computer Engineering received a message from high school student Connor Jin, asking for help with a science fair project. Jin, a rising junior from Syosett, New York, had read an academic paper about X-ray diffraction from Miller’s lab and reached out with an interest in contributing to similar work. “It was impressive to me that as a sophomore in high school, he had dug up an (arguably) obscure academic research paper and then read and understood it enough to write an informed and technically sound letter to me asking about working on a project,” says Miller.

Although Miller regularly collaborates with fellow Tufts faculty members, graduate and undergraduate students, and colleagues from companies and other universities, he had never mentored a high school student. He was intrigued by Jin’s request, and with confidence that Jin would have good local support, Miller agreed to act as a mentor.

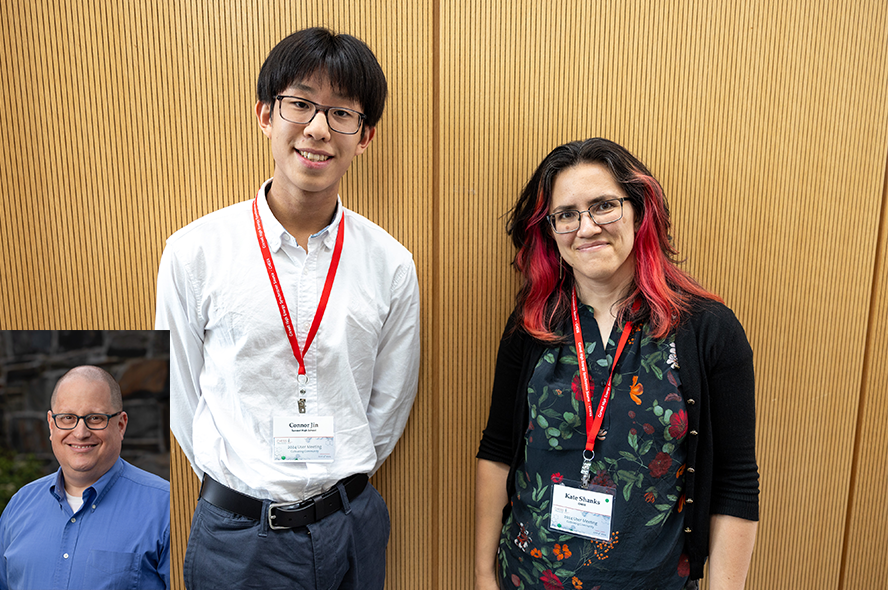

Based on Jin’s interests, Miller identified the FAST beamline project at the Cornell High Energy Synchrotron Source (CHESS) as a good match. Miller has collaborated with CHESS for the past decade. Jin joined Miller and co-mentor Dr. Kate Shanks, staff scientist at CHESS, in their ongoing work with a project funded by the Office of Naval Research.

CHESS is a high-intensity X-ray source with support from the National Science Foundation as well as the Air Force Research Lab which provides users with state-of-the-art synchrotron radiation facilities for research. The FAST beamline tests the properties of structural materials such as steel, aluminum, and titanium to determine their characteristics. In much the same as as doctors use X-rays to understand what is happening inside a patient, scientists such as Dr. Shanks and her colleagues use X-rays to ‘see into’ structural materials as different stresses are applied.

Figuring out how these different materials act under a range of loading scenarios helps ensure the strength and safety of products using these materials. For example, if a material is subject to a relatively small load, it will deform and return to its initial structure like an elastic rubber band that is stretched only a bit. But if it’s placed under a large load, the actual structure of the material will be altered, like silly putty that is stretched past its limit, a result known as plastic deformation. Determining the point at which the response shifts from elastic to plastic deformation is critical for engineers working with these materials and has applications ranging from automobiles to airplanes.

Working with Miller and Shanks, Jin used X-ray diffraction data to develop a working prototype of a machine learning method that could automatically detect important events in real time during CHESS experiments. For example, the method could determine the transition point from elastic to plastic deformation responses. Miller predicts that “these tools will quickly find their way into use at CHESS.”

Although it was Miller’s first time working with a high school student, he found the experience similar to working with a highly motivated undergraduate or graduate-level student. “While the level of mathematical sophistication was not the same (how could it be — Connor has not even taken calculus yet!), the interaction, discussions, and general dynamic was just remarkable,” said Miller.

Jin was awarded a gold medal at the 2023-24 Long Island Al Kalfus Math Fair and presented a poster titled "Image Analysis of Microstructure Dynamics in High Energy X-ray Diffraction" at the annual CHESS users group meeting. Now a rising high school senior, the experience helped Jin figure out his future path. “Working with Dr. Miller and getting involved with CHESS has deepened my interest in physics, which I now intend to pursue in future studies,” he said in a recent interview for the CHESS website. He plans to continue working on the FAST beamline project into his senior year.

Department:

Electrical and Computer Engineering