Creating microneedle patches

Think back to the last time you rolled up your sleeve for a vaccination – that familiar mix of anticipation and anxiety, knowing that a fleeting moment of discomfort is soon to follow. But what if transporting medicine through your skin could be much more comfortable and minimally invasive to your body?

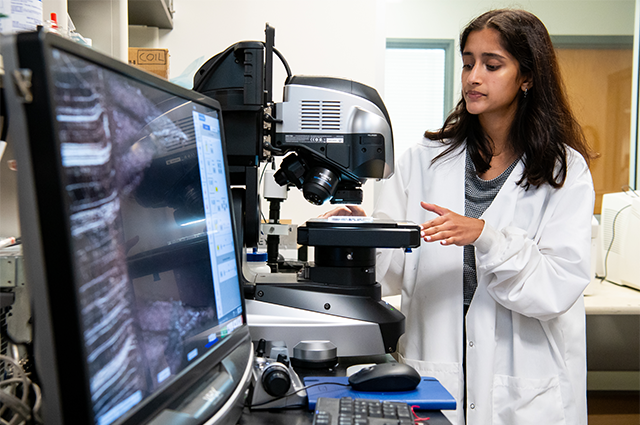

Meet Sanjana Vissapragada, E24, a rising senior majoring in biomedical engineering who spent her summer in the Tufts Nano Lab. With the guidance of postdoctoral scholar Dr. Atul Sharma and PhD student Hasika Suresh, Vissapragada worked on creating microneedle patches containing microneedles of different heights to release drugs in skin more efficiently, and she employed a novel laser ablation technique pioneered by the Nano Lab. This method of removing material from a solid surface with a laser beam offers a cost-effective, scalable approach to crafting microneedles – no cleanroom necessary. Moreover, the team is now in the process of developing a machine learning algorithm to determine the ideal shape and production settings for dissolvable microneedles made from PVP.

Vissapragada spent her summer at the Nano Lab thanks to support from Tufts University’s Summer Scholars program, which provides rising juniors and seniors from across departments and disciplines with funding to pursue ten-week independent projects. In the lab, Vissapragada created dissolvable microneedle patches with different substances like Sulforhodamine B, Ibuprofen, or just polyvinylpyrrolidone (PVP), which is preferred for its biocompatibility, water solubility, and controlled drug delivery. Then, she and the team took pictures using microscopes. To see how the needles released drugs, team members placed the patches over a buffer solution, which simulated the effect of microneedles dissolving as they come into contact with the interstitial fluid in the skin, and tested drug dispersion at different times. The researchers layered multiple pieces of parafilm, pressed the needles on them, and took microscope images of each film layer to understand the depth to which the microneedles penetrated skin.

When it came to training a machine learning algorithm that could enable more precise measurements, Vissapragada used the laser ablation method with varying speed and power settings to make molds, then poured PDMS silicon polymer on them. She measured the dimensions of the needles on the molds and used this info to teach the computer to suggest the best way to make microneedles of a specific size.

Vissapragada’s summer in the lab prepared her for future success – thanks, she says, to the Nano Lab mentors who guided her through systematic problem-solving and experiment design. One of her mentors, postdoctoral scholar Atul Sharma, felt it was important to volunteer as a Summer Scholars mentor due to his belief in the transformative power of mentorship and hands-on experience for fostering a deep understanding of research methodologies and cultivating critical thinking skills. "Sanjana’s hard work, dedication, and collaborative spirit significantly contributed to the positive outcomes achieved in our joint endeavors," says Sharma.

When Vissapragada first joined the project, her goal was to combine her backgrounds in biomedical engineering and computer science for a novel cause. Now she hopes her efforts will help make it possible to more easily treat medical conditions "such as on-demand drug release, and burn wounds where the skin thickness is not uniform and needles of different heights are needed to administer a treatment," without liver damage or risk of affecting the bioavailability of the drug. The microneedles are intended to enable consistent drug absorption and ease the delivery of drugs with small therapeutic windows.

In the future, Vissapragada would like to utilize her new knowledge and the skills she gained from working with the Nano Lab to enter the medical device or pharmaceutical industries. In the Nano Lab, principal investigator Professor Sameer Sonkusale and team seek to harness the machine learning algorithm to fashion microneedles with precise measurements, and to further enhance the laser ablation method.

Mentor Sharma has advice for any undergraduate student interested in research. "Embrace setbacks as learning opportunities, be persistent in the face of challenges, and remember that research is a journey of discovery and personal development," he says.